Ao comprar calçados de segurança, você encontrará diversos tipos de materiais. Cada material oferece benefícios únicos em termos de durabilidade e conforto. Por exemplo, o couro proporciona resistência e respirabilidade, enquanto o ajuste correto evita desconforto. Compreender essas opções ajuda você a escolher calçados adequados ao seu ambiente de trabalho e às suas necessidades pessoais.

Escolha calçados de segurança com material superior direito Para atender às suas necessidades. O couro oferece durabilidade e resistência à água, enquanto a microfibra proporciona conforto e facilidade de limpeza.

Selecione o material da biqueira adequado com base no seu ambiente de trabalho. As biqueiras de aço oferecem máxima proteção, enquanto as biqueiras de material composto são mais leves e não condutoras.

Procure palmilhas e entressolas de qualidade para aumentar o conforto. Materiais como o PU oferecem melhor suporte por longos períodos, enquanto as inserções de gel reduzem a fadiga.

Ao observar calçados de segurança, você percebe diversas partes essenciais trabalhando em conjunto para proteger seus pés. Os principais componentes de um calçado de segurança incluem o cabedal, o forro, a biqueira, a palmilha, a entressola, o solado e o sistema de fechamento. Cada parte utiliza materiais específicos para calçados de segurança, visando oferecer proteção, conforto e durabilidade. Compreender esses materiais ajuda você a escolher o calçado de segurança ideal.

A parte superior cobre a parte superior e as laterais do pé. A escolha dos materiais para a parte superior influencia a resistência, a respirabilidade e a impermeabilidade dos calçados de segurança. É comum encontrar couro, microfibra e tecidos utilizados nessa parte.

|

Material |

Vantagens |

Desvantagens |

|---|---|---|

|

Couro |

Alta durabilidade, conforto, resistência, isolamento térmico, respirabilidade e resistência natural a líquidos. |

Sensível a danos, requer cuidado, pode ressecar. |

|

Microfibra |

Macio, confortável, com resistência natural a líquidos e fácil de limpar. |

Pode descolorir se for de má qualidade e é sensível à luz solar. |

|

Tecidos |

Designs respiráveis, econômicos e versáteis |

Não é impermeável, mancha com facilidade e pode desbotar. |

O couro continua sendo um material popular para calçados de segurança devido à sua durabilidade, conforto e resistência natural a líquidos. Existem diferentes tipos de couro em calçados de segurança, cada um com qualidades únicas. O couro também isola os pés e permite que respirem. No entanto, o couro pode ressecar e precisa de cuidados regulares para manter sua qualidade.

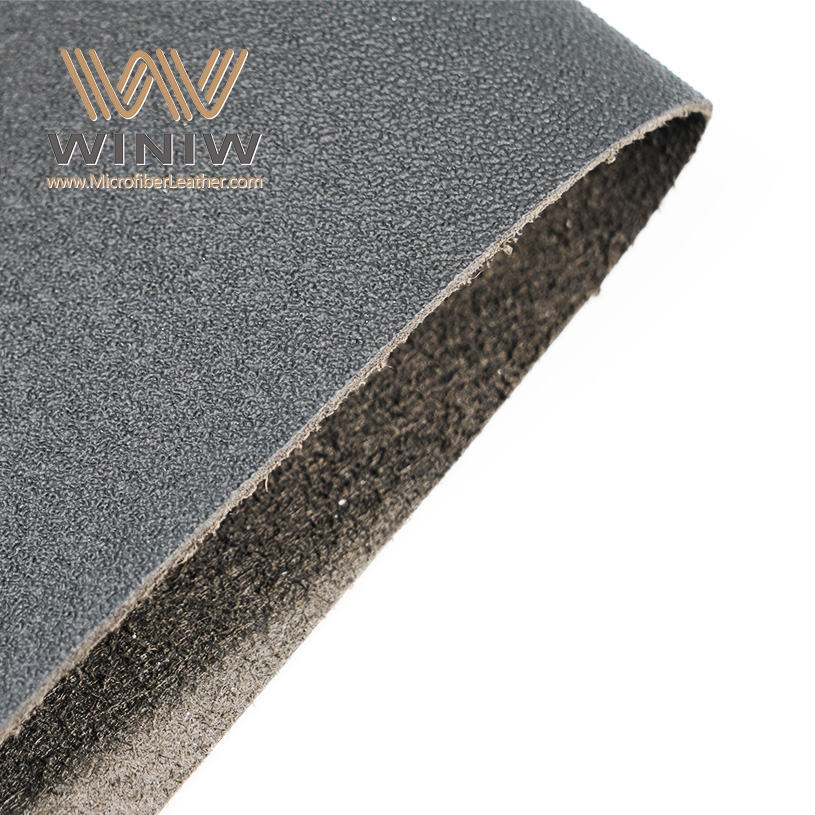

A microfibra destaca-se pela sua suavidade e conforto. Este material resiste a líquidos e é fácil de limpar. O couro sintético de microfibra oferece excelente resistência à abrasão, tornando-o ideal para ambientes exigentes. As fibras finas da microfibra permitem uma melhor circulação de ar, o que reduz a transpiração e a humidade. No entanto, a microfibra de baixa qualidade pode descolorir e ter uma menor durabilidade sob a luz solar.

Os cabedais têxteis proporcionam calçados de segurança leves e respiráveis. Esses tecidos oferecem opções econômicas e estão disponíveis em diversos modelos. Mantêm os pés frescos, mas não são impermeáveis. Os tecidos podem manchar ou desbotar com o tempo, portanto, é importante considerar o ambiente de trabalho ao escolhê-los.

Dica: Se você precisa de calçados de segurança resistentes à água, escolha modelos com cabedal de couro ou microfibra de alta qualidade.

O forro fica dentro dos seus sapatos de segurança e em contato com o seu pé. O material certo para o forro mantém seus pés secos, confortáveis e sem odor.

|

Material de forro |

Propriedades de gerenciamento de umidade |

|---|---|

|

Couro |

Excelente respirabilidade e absorção de umidade; adapta-se ao formato do pé para maior conforto. |

|

Têxteis padrão |

Absorve a umidade rapidamente e seca depressa; ideal para uso ativo ou em climas quentes. |

|

Têxteis termorreguladores |

Controla a temperatura, retendo o calor em ambientes frios ou proporcionando uma sensação de frescor em ambientes quentes. |

|

Membranas impermeabilizantes |

Cria uma barreira contra a água externa, permitindo ao mesmo tempo a evaporação do suor. |

Tecidos de malha e com propriedades de absorção de umidade são comuns em calçados de segurança. Os forros de malha melhoram a respirabilidade e ajudam o ar a circular ao redor do pé. Os forros com propriedades de absorção de umidade afastam o suor da pele, mantendo os pés secos e confortáveis. Muitos forros também possuem tratamentos antimicrobianos para controlar o odor, o que é importante para longas jornadas de trabalho.

|

Recurso |

Descrição |

|---|---|

|

Parte superior em malha respirável |

Proporciona ventilação e conforto. |

|

Forro que absorve a umidade |

Mantém os pés secos e confortáveis. |

|

Tratamento antimicrobiano |

Ajuda a controlar o odor. |

Você deve procurar por essas características se trabalha em ambientes quentes ou com alta atividade.

A biqueira é um componente essencial dos calçados de segurança. Ela protege os dedos dos pés contra quedas de objetos e compressão. Você pode escolher entre aço, alumínio e materiais compostos.

|

Tipo de biqueira |

Pontos fortes |

Pontos fracos |

|---|---|---|

|

Aço |

Proteção superior, durabilidade, isolamento térmico, custo-benefício |

Mais pesado que os outros |

|

Composto |

Leve, resistente à eletricidade, não magnético, não metálico. |

Pode não oferecer tanta proteção quanto o aço. |

|

Alumínio |

Leve, não magnético, resistente à corrosão, perfil mais fino |

Menos durável que o aço. |

As biqueiras de aço oferecem o mais alto nível de proteção e durabilidade. Elas atendem a padrões rigorosos de resistência a impactos e compressão. No entanto, o aço adiciona peso aos seus calçados de segurança e pode conduzir calor ou frio.

As biqueiras de compósito utilizam materiais como fibra de carbono, plástico, fibra de vidro e Kevlar. Essas biqueiras são mais leves que as de aço e não conduzem eletricidade nem calor. Funcionam bem em ambientes com riscos elétricos ou temperaturas extremas. As biqueiras de compósito ainda atendem aos padrões de segurança, mas as biqueiras de aço oferecem a maior resistência a impactos.

As biqueiras de alumínio oferecem uma opção leve com boa resistência à corrosão. São mais finas que as de aço, mas podem não durar tanto em condições adversas.

Nota: Verifique sempre as normas exigidas para o seu trabalho antes de escolher uma biqueira de proteção.

A palmilha e a entressola amortecem o pé e absorvem o impacto. A escolha do material dos calçados de segurança influencia o conforto e a saúde dos pés a longo prazo.

|

Material |

Durabilidade |

Conforto |

Peso |

Flexibilidade |

Resistência a condições adversas |

Custo |

|---|---|---|---|---|---|---|

|

Poliuretano (PU) |

Excelente |

Absorção de impacto superior |

Mais pesado |

Apoio equilibrado |

Resistente a óleo, produtos químicos e abrasões. |

Investimento de longo prazo com custo mais elevado |

|

Etileno-acetato de vinila (EVA) |

Bom, mas inferior ao PU. |

Leve e com boa absorção de impacto. |

Mais leve |

Extremamente flexível |

Menos resistente a condições adversas. |

Mais ecológico, mais barato |

As palmilhas de EVA são macias e leves. Elas absorvem bem o impacto, mas podem comprimir com o tempo. As entressolas de PU são mais densas e duráveis, oferecendo melhor suporte por longos períodos. As inserções de gel proporcionam amortecimento direcionado e retorno de energia, reduzindo a fadiga. O material certo da entressola distribui a pressão por todo o pé, o que ajuda a prevenir lesões como fascite plantar ou canelite.

Escolher os materiais certos para a palmilha e a entressola pode proteger suas articulações e manter o conforto durante longos turnos de trabalho.

A sola é a camada inferior dos seus sapatos de segurança. Ela proporciona aderência, resistência ao deslizamento e proteção contra objetos cortantes.

|

Avaliação |

Descrição |

|---|---|

|

SRA |

Testado em superfícies de azulejos cerâmicos tratadas com detergente, indicando aderência em áreas limpas e secas. |

|

SRB |

Testado em pisos de aço revestidos com glicerol, indicando desempenho em condições oleosas ou escorregadias. |

|

SRC |

Atende aos padrões SRA e SRB, proporcionando a maior resistência ao deslizamento em diversos ambientes. |

Solados de borracha oferecem excelente resistência ao deslizamento e durabilidade. Solados de PU são mais leves e resistentes a óleo, produtos químicos e abrasões. Solados de TPU são altamente responsivos e flexíveis, sendo ideais para atividades de alto impacto. Solados de PVC oferecem proteção com bom custo-benefício, mas podem não durar tanto quanto os de borracha ou PU.

Procure solados que atendam aos padrões SRC para obter a melhor resistência ao deslizamento em todos os ambientes.

O sistema de fecho influencia o ajuste dos seus sapatos de segurança e a facilidade com que os calça e descalça. Pode escolher entre atacadores tradicionais, velcro ou sistemas BOA.

|

Sistema de fechamento |

Durabilidade |

Satisfação do usuário |

|---|---|---|

|

BOA |

Alto |

Alto |

|

Velcro |

Médio |

Médio |

|

Cadarços tradicionais |

Médio |

Baixo |

Os cadarços tradicionais permitem ajustar a firmeza para um encaixe personalizado. São duráveis e fáceis de substituir. Os fechos de velcro oferecem fechamento rápido e são ideais para quem precisa tirar os sapatos com frequência. Os sistemas BOA utilizam um disco para ajustes rápidos e precisos, proporcionando um encaixe seguro. Os fechos BOA são duráveis e populares em diversos tipos de calçados de segurança.

Escolha o sistema de fechamento que melhor se adapte às suas necessidades de trabalho e preferências pessoais.

Agora você entende como a escolha dos materiais para o cabedal, forro, biqueira, palmilha, entressola, sola e sistema de fechamento influencia o desempenho dos calçados de segurança. Cada material desempenha um papel na proteção, no conforto e no atendimento às normas de segurança. Ao selecionar calçados de segurança, considere os riscos presentes no seu local de trabalho e as normas exigidas para a sua função. Esse conhecimento ajuda você a escolher os melhores calçados de segurança para as suas necessidades.

A escolha entre cabedal de couro e sintético afeta o desempenho dos seus sapatos de segurança no trabalho. O couro oferece alta resistência à abrasão e se molda ao pé, proporcionando excelente suporte e um ajuste personalizado. O cabedal sintético é mais leve e respirável, mas pode perder a forma e o amortecimento com o tempo. Veja as diferenças abaixo:

|

Recurso |

Couro |

Sintético |

|---|---|---|

|

Durabilidade |

Alta resistência à abrasão |

Propenso a rasgos |

|

Suporte para os pés |

Adapta-se ao formato do pé, oferecendo ótimo suporte. |

Perde a forma com o tempo. |

|

reparabilidade |

Pode ser reparado. |

Geralmente não é reparável |

|

Impermeabilização |

Resistência natural, sustentável |

Depende de membranas |

|

Peso/Respiração. |

Mais pesado, menos respirável |

Mais leve e respirável. |

O couro precisa de produtos de limpeza especiais e secagem ao ar livre, enquanto materiais sintéticos Limpa-se facilmente com água e sabão.

As biqueiras de aço adicionam de 200 a 300 gramas aos calçados de segurança, o que pode causar fadiga durante longos turnos. As biqueiras compostas, feitas de materiais como Kevlar ou fibra de carbono, pesam de 30 a 40% menos e reduzem a fadiga. Ambos os tipos atendem às especificações de segurança para resistência a impactos. As biqueiras compostas também não conduzem eletricidade, tornando-as ideais para trabalhos com eletricidade.

Em ambientes elétricos, tanto as biqueiras de aço quanto as de material composto passam nos testes de risco elétrico, desde que o calçado de segurança possua a designação EH adequada.

A escolha do solado influencia a resistência ao deslizamento e a produtos químicos. Solados de borracha oferecem resistência superior a cortes e perfurações, além de suportarem altas temperaturas (até 300 °C). Solados de poliuretano (PU) e poliuretano termoplástico (TPU) resistem a óleo, ácidos e combustíveis, sendo adequados para fábricas e laboratórios. O desenho da sola e os compostos de borracha melhoram o desempenho antiderrapante, especialmente em superfícies molhadas ou irregulares. Sulcos profundos são mais eficazes em áreas lamacentas, enquanto padrões mais fechados são mais adequados para ambientes internos.

Ao escolher calçados de segurança, considere conforto, durabilidade, resistência ao deslizamento e proteção. Para construção civil, opte por palmilhas antiperfuração e biqueiras de aço. Para trabalhos elétricos, procure calçados com classificação EH e biqueiras de compósito. Indústrias químicas exigem solados impermeáveis e calçados antiderrapantes. Sempre verifique as especificações de segurança para que sejam adequadas ao seu ambiente de trabalho.

Você deve sempre escolher calçados de segurança adequados ao seu ambiente de trabalho. Selecione materiais que ofereçam um equilíbrio entre proteção e conforto, como couro para maior durabilidade ou materiais sintéticos para maior flexibilidade. Calçados de alta qualidade reduzem o risco de lesões e duram mais. Considere a impermeabilização, a proteção para os dedos e o amortecimento para manter seus pés seguros e confortáveis todos os dias.

Você usa sapatos de segurança para proteger seus pés de lesões no trabalho. Esses sapatos protegem contra impactos, perfurações e escorregões em diversos ambientes perigosos.

Primeiro, verifique os riscos no seu local de trabalho. Selecione calçados de segurança com características como biqueira de aço, solado antiderrapante ou materiais impermeáveis Com base nas suas necessidades.

Você precisa substituir os sapatos de segurança quando notar danos visíveis, solas desgastadas ou desconforto reduzido. Inspeções regulares ajudam a manter você seguro e confortável no trabalho.

Digitalizar para wechat: